Control valve precision spray CNC EDM machine

In order to meet market demand, improve processing efficiency of micro-spray EDM of the control valve, develop a control valve orifice EDM machine equipped with double-station processing capability.

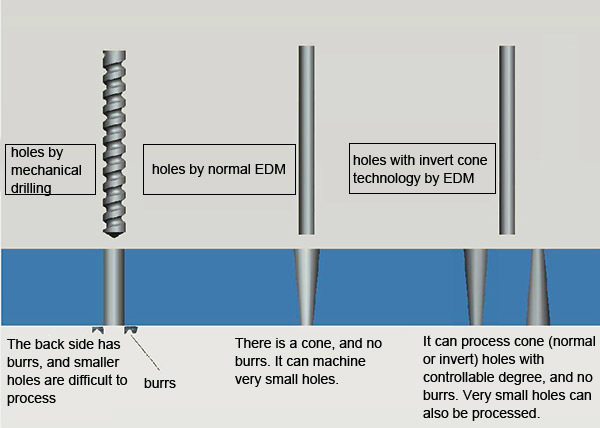

1. The inverted cone mechanism can process holes of various specifications and shapes to meet the requirements of the high-end control valve for the hole shape;

2. Perfect combination of high frequency vibration and micro electric discharging technogy improves the quality and efficiency of the micro-hole machining process.

3. Unique wire feeding and withdrawing structure achieves self compensating and automatic trimming of electrode wire, and guarantees the precision and conformity of holes.

4. With double-station setup and two separate EDM unit, it is capable of machinig two products of different specification. Occupying less floor space and improving the efficiency.

Description

|  |

| Comparison of the machining process for injection nozzles | Double-station |

|  |

| High technology and performance | Control valve |

Machine main parameter

| Total weight | 1500kg |

| W×D×H/ size | 1230mm×1760mm×2100mm |

| Total power | 5KW |

| Supply voltage | 220V/50Hz |

| Control panel size | 545mm×545mm×155mm |

| Worktable size | 980mm×680mm |

| X, Y, Z Range | 90mm, 30mm, 110mm |

| W×D×H/ Tank outer size | 950mm×500mm×500mm |

| TTank capacity | 66L |

| Water supply & flow rate | 0.3kg/cm², 30L/h |

Machine main parameter

| Machining size& precision of hole | 0.125mm~0.5mm/≤±0.002mm |

| Rate of diameter and depth | 1:10 |

| Tungsten electrode attrition rate | 5:1 |

| Machining surface roughness | Ra≤0.6μm |

| Single hole processing time | <50s |

| X, Y position precision | ≤±0.005mm |

| Dispersion of flow | ≤±3% |

| Back taper | ≤2° |